Key Fasteners Used in Mining Machinery: What You Need to Know

In the mining industry, small components often carry the biggest weight. One such component? Fasteners. Whether it’s holding together massive drilling rigs, securing pump systems, or reinforcing conveyor structures, fasteners are essential to mining machinery.

This article walks you through the key fasteners used in mining and takes a deep dive into the growing demand for custom fasteners in the industry. We’ll also explore how quality fasteners reduce downtime, improve safety, and boost efficiency.

Why Are Fasteners Critical in Mining?

Fasteners ensure mining equipment’s structural integrity and safe operation, even in extreme environments. From high vibration to corrosive exposure, mining machinery demands fastening systems to withstand it all. The mining, oil, and gas fastener market has grown rapidly because secure, reliable connections aren’t optional—they’re operational lifelines.

Heavy-Duty Applications for Mining Fasteners

- Fasteners in Drilling Rigs

Drilling equipment operates under high impact and constant vibration. Fasteners must maintain structural tightness while enduring torque, temperature, and geological stress. High-strength bolts and lock washers are commonly deployed.

- Fasteners in Mining Pumps

Mining pump fasteners must resist both corrosion and pressure fluctuations. These systems often operate in wet, abrasive conditions where stainless steel bolts or coated fasteners are ideal.

- Fastener Used in Securing Pipes

Conveyance pipelines for slurry, water, or chemicals rely heavily on strong, leak-proof fasteners. Bolted flange connections with gaskets and proper torque settings are standard. Using the wrong fastener can lead to joint failure or environmental hazards.

Types of Mining Fasteners You Should Know

- Bolts and Nuts

These are the most commonly used mining fasteners in various grades to suit different load and environmental needs. High-tensile bolts are essential for supporting heavy machinery frames.

- Washers

Flat and lock washers help distribute load and prevent loosening in high-vibration scenarios, such as crushers or conveyors.

- Rivets

Rivets are used in semi-permanent or permanent joints, especially in structural frames or confined spaces.

- Anchors

Anchors provide foundational support by securing machinery to concrete bases. Expansion anchors and chemical anchors are typical choices.

- Screws

Self-tapping screws are useful for temporary setups or easy-to-maintain enclosures where drilling or threading isn’t feasible.

- Pins and Studs

Pins, dowels, and stud bolts are employed to align parts or secure components with limited space or access.

The Growing Demand for Custom Fasteners for the Mining Industry

Custom fasteners for mining industry applications are more than just a trend—they’re necessary. Standard fasteners often fail to meet the unique stress, size, and environmental challenges mining sites pose. Here’s why customization matters:

1. Tailored Design for Complex Equipment

Mining equipment designs can be complex, with unique geometries and load paths. Custom fasteners allow for a precise fit and enhanced reliability.

2. Advanced Materials for Harsh Conditions

Custom fasteners can be manufactured from corrosion-resistant alloys, heat-treated steels, or coated materials. This is particularly crucial for advanced fastening systems, mining, and industrial setups.

3. Extended Equipment Life

When fasteners fit better and resist environmental wear, they contribute directly to longer machinery life and reduced failure rates.

4. Support for Niche Applications

From securing underground ventilation to China mining pump fasteners, tailored solutions reduce mismatch risk and boost performance.

5. Improved Assembly Efficiency

Custom designs can reduce installation time with features like pre-threaded ends or integrated locking systems, minimizing downtime.

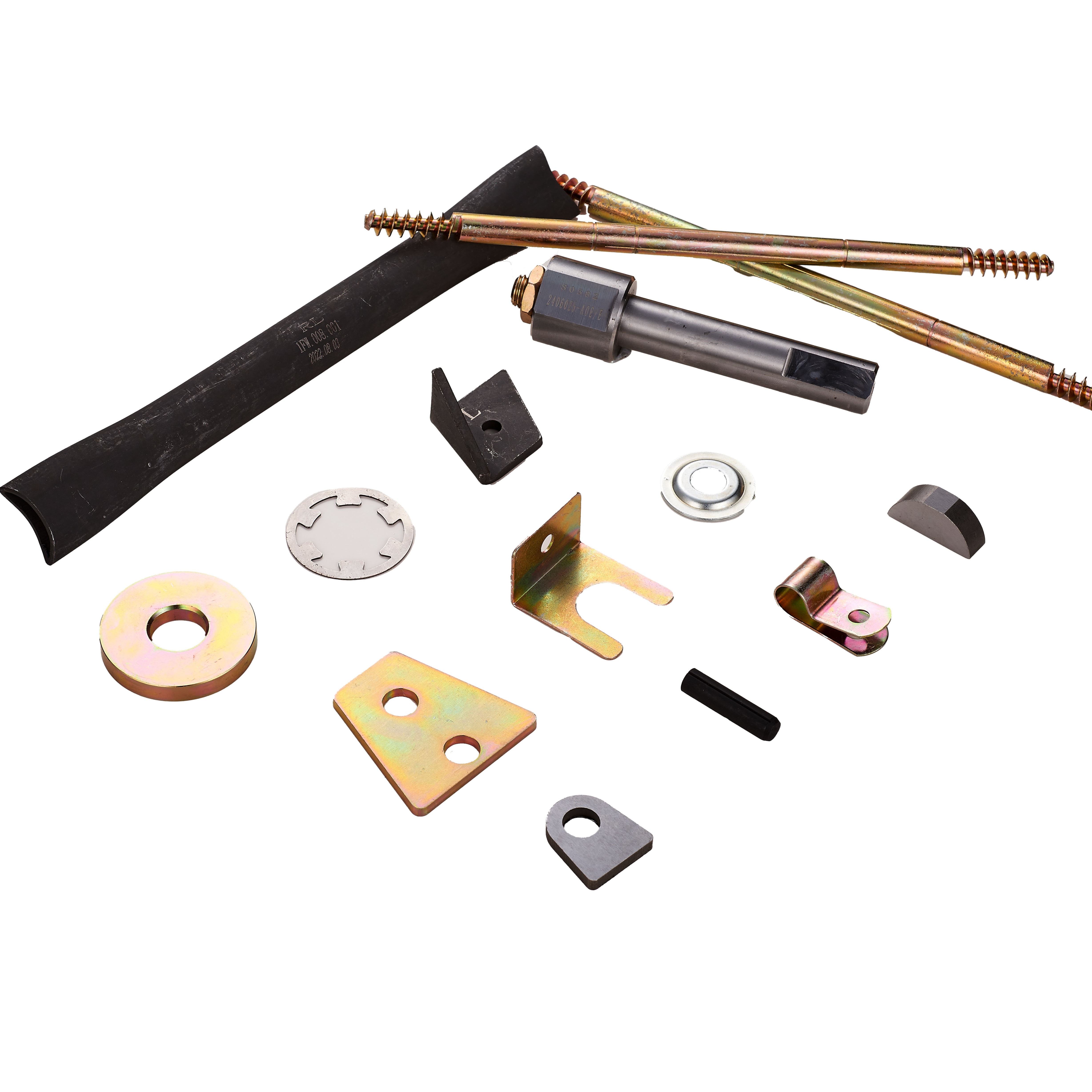

Recommended CNRL Fasteners for Mining Equipment

CNRL Fasteners provides high-strength, reliable fastening solutions for demanding mining environments. Below are some of the top fasteners we recommend for use in heavy machinery, pipelines, and pump systems.

1. Socket Shoulder Bolts

Grade 12.9 | High Load-Bearing | Superior Shear Strength

Socket Shoulder Bolts High Tensile 12.9 Grade Allen Shoulder Head Screw M5 M6 M8 M10 M12

More DetailsEngineered for demanding applications with high lateral force. Perfect for mining rigs and joint connections.

🔗 View Product

2. Custom Self-Drilling Screws

Zinc Plated | Quick Installation | Corrosion Resistant

Customized self drilling screws Din 7504 galvanized flat head drywall screws course thread

More DetailsSuitable for sheet metal and modular assemblies in field installations. Saves time and increases assembly efficiency.

🔗 View Product

3. OEM Blind Rivets

Permanent Fixing | Tight Grip | Lightweight Materials

OEM blind rivets types of automotive rivet

More DetailsIdeal for areas where access is limited to one side, it is widely used in conveyor frame assemblies and light structural units.

🔗 View Product

4. Automotive Engine Fasteners

Automotive engine fasteners bushing washer bolts

More DetailsIncludes Bolts, Washers, Bushings | High Durability | Precision Fit

Designed for mining pump fasteners and engine assemblies. Built to last in wet and high-pressure environments.

🔗 View Product

These mining fasteners are durable, high-performance, and customizable to meet specialized needs. Contact us to learn how CNRL can support your operation with custom fasteners for mining industry applications.

FAQ: Mining Fasteners Explained

What are mining fasteners?

Fasteners used in mining machinery to connect, secure, or support structural and moving components.

Why are custom fasteners better for mining?

They match specific machinery needs, resist wear, and last longer in harsh environments.

What fastener is used in securing pipes?

Bolted flange systems using high-strength bolts and washers.

What are mining pump fasteners?

Corrosion-resistant fasteners are used in pump systems handling abrasive or wet media.

What trends are shaping the mining fastener market?

Increased use of advanced fastening systems and demand for tailored, high-durability fasteners.

Conclusion: Small Parts, Big Impact

In a high-stakes industry like mining, every detail matters. Fasteners may seem small, but their role is massive. From standard bolts to custom-engineered solutions, using the right mining fasteners means fewer breakdowns, better safety, and lower maintenance costs.

If you’re in the mining sector looking for durable, precision-made fasteners, CNRL Fasteners delivers. With years of expertise and a catalog of tailored solutions, we help you build and maintain systems that perform under pressure.