What Are Railway Fasteners? Key Components and Their Role in Track Safety

From the platform, a piece of track looks simple: two steel rails and a bed of stone. But anyone who buys or maintains railway hardware knows the real work is done by the components hidden around and underneath the rail. Those small parts are the fastening system in railway infrastructure that quietly holds everything together.

For OEMs, distributors, and maintenance contractors, understanding how a modern fastening system in railway projects is built and which parts are most critical makes it easier to specify the right products, avoid premature failures, and support safe, reliable operations.

What Is a Railway Track Fastening System?

A railway track fastening system is the collection of mechanical parts that connect the rail to the sleeper (or tie), keep the gauge correct, and control movement under load. Instead of thinking about each bolt or clip in isolation, it helps to view the assembly as a complete rail fastening arrangement.

In a conventional ballasted line, the system around the rail foot usually includes fishplates and fish bolts at the joints, clips or clamps that press the rail onto the baseplate, and spikes or screws that secure the baseplate to the sleeper. Nuts, washers, pads, and other hardware spread the load and resist loosening so the track can survive high traffic and changing temperatures.

Together, these fasteners in railway track construction maintain alignment, manage vibration, and protect sleepers, ballast, and subgrade from excessive stress.

Key Components of Railway Fasteners

Different countries and networks use different designs, but the main elements of a railway fastening system tend to be similar. Below are the components most buyers encounter and what they do in the track structure.

Fish Bolts – Securing Rail Joints

Fish bolts connect fishplates (joint bars) to the ends of adjacent rails. Their job is to keep the running surface continuous so wheels transfer smoothly from one rail section to the next.

To do this well, a fish bolt must deliver high clamping force, hold its torque despite vibration and temperature cycles, and resist corrosion over long periods outdoors. Because joints are natural weak points in the line, the quality of these railway fasteners has a direct impact on ride comfort and safety.

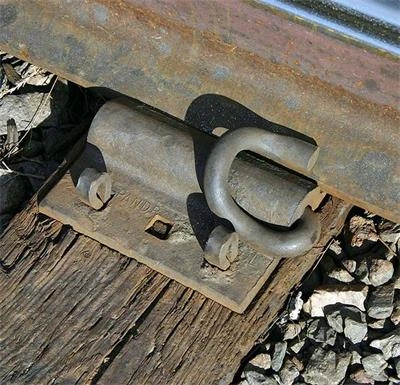

Rail Clips – Holding the Rail in Position

Rail clips apply downward and lateral pressure on the rail foot, holding it firmly against the baseplate and sleeper. Elastic clip systems add controlled flexibility so the track can absorb impact loads from passing axles rather than transmitting them straight into the sleeper.

Good clip design keeps the rail in gauge under heavy traffic, limits wear on the rail foot and baseplate, and reduces noise and vibration passed into the sleeper and ballast. On many concrete-sleeper lines, the clip, shoulder, and insulator form one integrated assembly tailored to the specific rail profile and support conditions.

Dog Spikes and Screw Spikes – Classic Timber Sleeper Solutions

On timber sleepers, dog spikes or screw spikes are still widely used. Dog spikes have an offset head that grips the rail base or baseplate, while screw spikes provide a threaded connection into the wood.

Both options hold the rail and plate securely to timber sleepers, offer strong pull-out resistance when correctly installed, and are straightforward for track crews to drive or remove during maintenance. Even as networks upgrade to newer systems, these traditional fasteners remain common on industrial sidings, branch lines, and low-speed routes.

Supporting Hardware – Nuts, Washers, Plates, and Pads

Around the main components, you’ll find a large family of supporting parts: track bolts, nuts, plain and spring washers, baseplates, and resilient pads.

These parts spread load over a wider area, protect the sleeper material from crushing, prevent nuts from backing off under vibration, and, where required, provide electrical insulation and extra damping. Treating them as simple commodities can be risky; small variations in hardness, dimensions, or coating thickness can undermine an otherwise well-designed fastening assembly.

How Fasteners Protect Track Safety and Performance

When a train passes, every wheel generates vertical, lateral, and longitudinal forces. The fastening system in railway tracks has to manage all of these without allowing the rail to move out of position.

Maintaining Gauge and Alignment

Fish bolts, clips, spikes, and plates work together to hold the rail at the correct spacing and cant angle. If any part becomes loose or worn, the gauge can widen or tighten, which accelerates wear on wheels and rail heads and, in extreme cases, increases derailment risk.

Controlling Vibration and Load Transfer

A well-matched railway fastening system spreads load from the rail into the sleeper and ballast while also damping vibration. By avoiding point loading and excessive movement, it extends rail and sleeper life, reduces ballast degradation, and helps keep noise within acceptable limits in urban areas.

For owners and operators, that means fewer speed restrictions, fewer emergency call-outs, and a lower whole-life cost for the line.

Supporting Efficient Inspection and Maintenance

Fastener choice also affects how easy the track is to maintain. Consistent geometry, clear markings, and durable coatings help maintenance teams spot problems quickly during visual inspections, retighten or replace components with standard tools, and plan renewals with confidence in service life expectations.

In performance-based contracts, where suppliers are measured on uptime and condition, these details can make the difference between profit and penalty.

What Buyers Should Expect from Railway Fastener Manufacturers

For distributors, OEMs, and EPC contractors, buying hardware for a fastening system in railway projects is really about managing risk. Poorly controlled parts can cause assembly problems, premature loosening, or inconsistent behavior in service.

That’s why many buyers look for railway fastener manufacturers that can supply complete sets of compatible bolts, clips, spikes, nuts, and washers, work from international standards or customer drawings, and provide test reports and material certificates with every batch. The ability to scale from pilot orders to large production runs without quality drift is also essential.

CNRL’s Role as a China Railway Fastener Supplier

As a China railway fastener specialist and OEM manufacturer, CNRL Fastener supports global distributors with application-ready hardware for rail projects. Building on decades of experience in critical fasteners, CNRL can supply:

- Fish bolts, track bolts, and hook bolts

- Nuts, washers, and spring washers

- Clips, spikes, and related hardware

- Custom components based on drawings or standards

Working with a single partner for the fastening system in railway projects means:

- Better compatibility across bolts, nuts, washers, and clips

- Fewer dimensional surprises during installation

- Simplified logistics and inventory management

Buyers can explore the wider fastener product range for more details on high-strength bolts, nuts, and washers designed for demanding railway and infrastructure applications here: Fastener Product Range

For a deeper dive into bolt selection specifically, you can also reference this application blog explaining different types of bolts in railway systems: Understanding Types of Bolts in Railway Systems.

These resources help distributors move beyond basic catalog listings and position themselves as knowledgeable partners in specifying safe railway fasteners for different track conditions.

Conclusion

Fish bolts, clips, spikes, and washers may be small, but they determine how well a fastening system in railway lines performs over decades. When each component is matched to the rail profile, sleeper type, climate, and traffic level, the result is a stable, low-maintenance track structure that keeps people and cargo moving safely.

For OEMs, EPC contractors, and distributors, the next step is to treat every fastener as a safety-critical component, check that each element in the assembly works together as a system, and partner with specialists who understand both track engineering and production quality.

Key Takeaways

- A railway track fastening system is a complete assembly of bolts, clips, spikes, plates, and pads that hold the rail in place and manage loads.

- The quality of fish bolts, clips, and supporting hardware has a direct impact on gauge, vibration, and long-term maintenance costs.

- Working with proven railway fastener manufacturers like CNRL helps buyers reduce risk, improve compatibility, and support safer, more reliable rail networks.

FAQs

Q1: What is the main purpose of railway fasteners?

A1: Railway fasteners connect the rail to the sleeper, maintain the correct gauge and rail cant, and control movement under load. By doing this, they protect the track structure from damage and keep trains running safely and smoothly.

Q2: Which components are usually included in a railway fastening system?

A2: A typical assembly will include fishplates and fish bolts at joints, rail clips or clamps, dog spikes or screw spikes, baseplates, rail pads, and matching nuts and washers. The exact mix depends on sleeper type, rail profile, and operating conditions.

Q3: How often should track fasteners be inspected?

A3: Inspection frequency depends on traffic density and environment, but fasteners are normally checked during routine track patrols and after major weather events or heavy maintenance work. Any loosened, damaged, or corroded parts should be tightened or replaced promptly.

Q4: Are modern clip-based systems better than traditional dog spikes?

A4: Elastic clip systems generally provide better control of rail movement, improved vibration damping, and easier prediction of service life. However, dog spikes remain a practical, proven option for many timber-sleeper lines, low-speed routes, and industrial sidings.

Q5: What should I look for in a supplier of railway fasteners?

A5: Look for a supplier that understands rail standards, can provide consistent dimensional control and surface treatments, and is able to document testing and material traceability. Experience with complete track assemblies, rather than single parts in isolation, is a strong advantage when you are sourcing components for demanding railway projects.