From TS16949 to IATF 16949: How Fastener Manufacturers Can Rapidly Adapt to Certification Challenges

With the global automotive industry constantly raising the bar for quality, ts16949 certification has been replaced by the upgraded iatf 16949 certification. For automotive fastener suppliers, this change represents not only a compliance requirement but also an opportunity to strengthen quality systems and enhance market competitiveness.

Understanding the difference between iatf 16949 and ts16949 is critical for fastener factories aiming to remain at the forefront of the industry.

1. Deep Understanding of IATF 16949’s New Requirements

What does IATF stand for? The International Automotive Task Force (IATF) is a group of automotive manufacturers and trade associations responsible for the development of the IATF 16949 standard. Compared to TS16949, the iatf standard introduces enhanced requirements in areas like risk management, product safety, and supplier development.

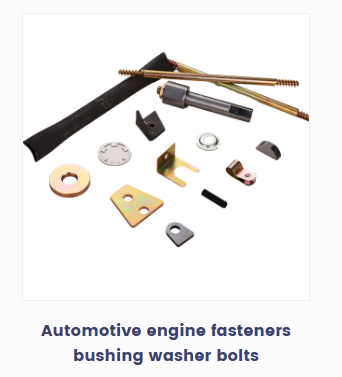

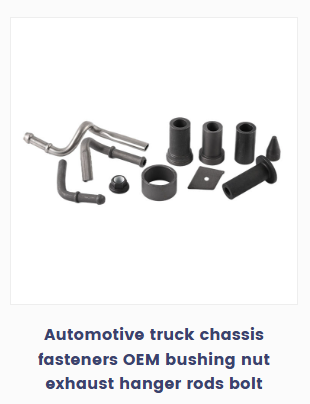

Both custom fastener suppliers and oem fastener suppliers need to provide thorough training for their teams to ensure full understanding of these new demands. Training should address not only the theory but also the practical implications of the standard for daily operations.

2. System Review and Gap Analysis

Understanding the difference between iatf and iso is also vital, as IATF 16949 builds on ISO 9001 but adds sector-specific automotive requirements. Fastener factories must set up a dedicated team to perform a detailed review of their existing ts16949 certification systems and identify what needs to be updated. Key steps include:

- Risk Identification and Countermeasures: Identify possible disruptions and establish robust contingency plans.

- Product Safety and Traceability: Implement traceability solutions that allow for quick verification—a core aspect when customers want to know how to check iatf certificate validity.

- Process Capability and Control Plans: Use data-driven methods for each step, ensuring robust process control.

- Supply Chain Management: Encourage your suppliers to pursue their own iatf 16949 certification, boosting supply chain reliability.

3. Internal Audits and External Expert Guidance

The iatf 16949 certification cost may vary, but effective preparation is crucial to success. Factories should enhance their internal audit practices and invite third-party experts for periodic reviews. Documented procedures, internal training, and management reviews will ensure compliance with the iatf standard and help avoid costly certification delays.

4. Accelerating Information Technology and Automation Upgrades

Digitalization is not just a trend—it is an integral part of meeting iatf 16949 certification requirements. By implementing systems like MES and ERP, both custom fastener suppliers and oem fastener suppliers can achieve data transparency, rapid traceability, and streamlined audit processes.

5. Audit Preparation and Efficient Collaboration

Before the official audit, organize all necessary documentation such as process flow charts, control plans, PPAP files, and internal audit reports. Assign responsibilities and ensure cross-departmental communication for a smooth and successful certification.