Selezione di bulloni esagonali pesanti per applicazioni industriali

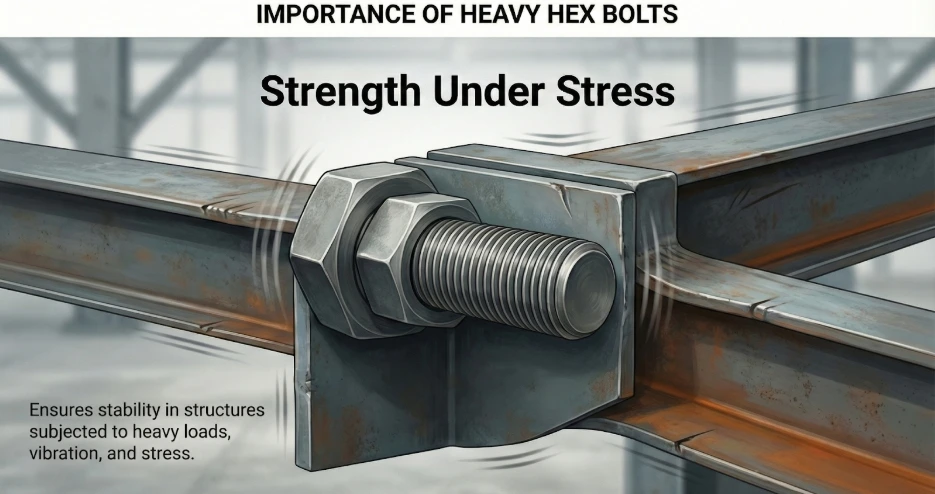

Industrial structures require fasteners that maintain strength under load, vibration, and stress. Heavy hex bolts fill this role by offering high clamping force and mechanical stability.

A hex head bolt features six sides for wrench installation and controlled torque transfer. Engineers rely on hex bolts in structural joints where failure is unacceptable.

To learn more about the nitty-gritty of hex bolts, continue reading below.

Why Strength Matters in Heavy Duty Applications

Heavy machinery and infrastructure create demanding mechanical conditions. Trucks experience vibration and twisting forces during normal operation. Bridges and wind turbines face dynamic loads from traffic and wind.

These stress conditions aim to loosen or deform fasteners. Strong bolted joints prevent movement between connected parts. Proper fastener selection maintains structural integrity and safety.

Sizing, Fit, and Dimensional Considerations

Sizing affects performance and assembly efficiency. An engineer uses a hex bolt sizes reference to select diameter, length, and thread engagement. A correct fit prevents stripped threads and joint weakness.

Dimensional charts assist communication between engineers, buyers, and factories. A hex bolt dimensions chart outlines head widths, thread lengths, and wrench sizes. Standard dimensions enable consistent sourcing and installation.

Hex Bolt Dimension Reference Table

| Parametro | Descrizione |

| Nominal Diameter | Bolt diameter measured across the threaded section |

| Thread Length | Length of threaded area for nut engagement |

| Shank Length | Unthreaded length that carries shear loads |

| Larghezza della testa | Distance across flats for wrench sizing |

| Head Height | Thickness of the head above the surface |

This table format helps clarify specification expectations. It also reduces errors during ordering and production reviews.

Explore our comprehensive range of standard and custom hex bolts available in various grades and surface finishes.

Maggiori dettagliMaterials and Strength Grades

Material selection influences mechanical behavior and service life. Alloy steel provides high tensile strength and controlled hardness. Specialty coatings help resist corrosion in outdoor or marine environments.

Strength grades define how a bolt behaves under tensile and shear forces. Higher grades support larger loads and resist deformation. Coatings such as galvanizing or zinc protect against rust and chemical exposure.

Inspection and Quality Assurance

Heavy-duty fasteners undergo more testing than standard hardware. Inspection confirms that parts meet specified strength and material requirements. CNRL uses several advanced inspection methods for verification.

Friction Coefficient Testing

This test measures the tightening characteristics between threads and surfaces. Variations in friction alter the clamping force under specified torque. Stable friction values support predictable installation results.

Mechanical Testing

An electro-hydraulic servo universal testing machine verifies tensile and yield strength. This equipment simulates real forces applied to fasteners. Test data confirms that batches meet engineering standards.

Material Composition Analysis

Element analysis confirms correct alloy formulation. Chemistry affects hardness, ductility, and fatigue resistance. Precise composition improves long-term structural performance.

CNRL Quality: Field Proven Performance

Laboratory testing builds confidence, but field results prove capability. CNRL fasteners have seen use in demanding equipment and infrastructure. These applications validate the performance of the fasteners in real stress environments.

Cooperation with FAW Jiefang and Dongfeng Motor demonstrates durability in commercial vehicles. Trucks deliver continuous vibration, torque change, and thermal cycling. Structural fasteners must tolerate these conditions without loosening or breaking.

Installation Best Practices to Remember

Even high-strength parts fail when incorrectly installed. Bolts must be tightened to specified torque values. Torque tools help maintain consistent preload across joints.

Under-tightening reduces clamping force and increases vibration loosening. Over-tightening stretches threads and weakens material strength. Rondelle help distribute force and protect surfaces during tightening.

Common Selection Mistakes You Can Avoid

One mistake is using general hardware for structural applications. Standard hardware does not support high dynamic loads. Structural joints require engineered fasteners designed for industrial forces.

Another mistake is ignoring environmental exposure. Corrosion can reduce the cross-section and weaken the joint. High humidity or marine environments require protective coatings or stainless materials.

Working with Suppliers and Manufacturers

Buyers often need customized dimensions or materials for special projects. Working with a supplier that understands heavy-duty requirements improves results. A non-standard fastener supplier can tailor geometry to engineering drawings.

Factories, such as CNRL, support more customization than generic distributors. A non-standard fastener factory can adjust thread length, coatings, or alloy grade. Regional suppliers, such as China non-standard fasteners producers or non-standard fasteners India manufacturers, support large batch production and global delivery.

Documentation from suppliers helps with verification and quality control. Reports from friction tests, mechanical tests, and chemical analysis support traceability. This documentation increases confidence for industrial customers.

Conclusione

Selecting the right heavy hex bolts for industrial applications begins with understanding load conditions, environments, and sizing standards. Proper inspection ensures that materials, mechanical properties, and coatings meet engineering requirements.

Plus, combining proper installation with verified quality control creates structures that can withstand high forces and dynamic loads.

What’s even more important to remember is that Industrial equipment and infrastructure depend on fasteners that sustain performance under stress, which makes careful fastener selection and validation essential.

To get started with your hex bolt inquiries, contact CNRL today.